Artificial Anatomy

Within this research area the aim is to develop validated artificial structures like bones and soft tissue which are the main part of the patient phantom and elementary for imitating a realistic haptic feedback.

Artificial Bones

Surgical interventions within the area of orthopaedic surgery require to cut, drill or to penetrate bones. Artifical bones incoporated into the patient phantom should be able to imitate the human bone as good as possible in order to achieve a realistic haptic feedback. Depending on the chosen surgical intervention this haptic feedback is characterized e.g. by

- the needle insertion force during penetration of the vertebra (see Figure 1 and Figure 2) for cement augmentation techniques,

- the torque when inserting a screw for osteosynthesis, or

- the cutting forces when sawing, drilling or milling bone tissue during orthopaedic surgery.

|

|

| Figure 1: Measuring the needle insertion force for an artificial vertebra. | Figure 2: Validation by measuring needle insertion forces with human specimen. |

The development of artificial bones structures requires to incorporate different rapid prototyping technologies including 3D-printing or molding using different materials for imitating cortical as well as trabecular bone. Since both bone tissues differ in mechanical properties as well as in morphology, materials with quite different processing properties have to be balanced. For the realization of artificial vertebrae, used in a cement augmentation simulator, the trabecular bone is imitated by a PU foam recipe. The PU foam is casted into resin shells with different material properties and thickness and shows up realistic needle insertion forces compared to human specimen [1], [2].

Current research topics are the improvement of the trabecular structure to allow balloon dilatation as well as cement injection. The cortical layer is going to be improved in order to allow screw insertion, cutting and milling.

Artificial Soft Tissue

Artificial muscles and connective tissue can be made of silicone. Silicone rubber is chosen as basic material. Silicone oils are added to the silicone rubber in different amounts of the whole rubber mass in order to achieve a more realistic viso-elastic behaviour and to provide a kind of lubrication, when penetrating the soft tissue. An artificial structure with different layers can be achieved, if discrete layers of silicone with distinct ratios of silicone rubber and silicone oil a stacked together.

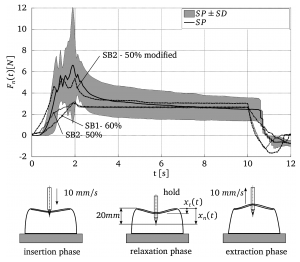

In order to validate artificial tissue blocks, biomechanical measurements on human tissue specimen are performed and compared to the artificial tissue samples. In case of cement augmentation techniques, soft tissue is penetrated by the needle and hence the the needle insertion force qualifies as characteristic parameter. Since human soft tissue exhibits distinct visco-elastic behaviour, insertion measurements are performed in three phases (Figure 3): insertion – relaxation – extraction. During insertion phase the needle is inserted into specimen with predefined insertion depth and feed rate (phase 1=insertion). In the relaxation phase the needle is stopped for a certain amount of time (phase 2=relaxation). Finally the needle is removed again with predefined feed rate (phase 3=extraction). In [3] it is shown, that an artificial tissue block made of silicone imitates human muscle tissue with tendon and skin quite well.

Current research directions are going to consider the implementation and investigation of layered structures and structures with incorporated fibres as well as artificial intervertebral discs.

[Bibtex]

@Article{Fuerst2012a,

Title = {Foam phantom development for artificial vertebrae used for surgical training.},

Author = {Fuerst, David and Stephan, Daniel and Augat, Peter and Schrempf, Andreas},

Journal = {{Conf Proc IEEE Eng Med Biol Soc}},

Year = {2012},

Pages = {5773--5776},

Volume = {2012},

Abstract = {Currently the surgical training of kyphoplasty and vertebroplasty is performed on patients or specimens. To improve patient safety, a project was initiated to develop an Augmented Reality simulator for the surgical training of these interventions. Artificial vertebral segments should be integrated to provide realistic haptic feedback. To reach this, resulting forces during needle insertions (trans- and extrapedicular) into formalin-fixed vertebral specimens were measured. The same insertion procedure was also performed on six customized polyurethane blocks with varying mechanical parameters. Based on the results of these measurements, a specific foam phantom was generated and the insertion force measured. Additionally a parametric model for the needle insertion into bone was designed calculating three characteristic parameters for all insertion measurements. The resulting insertion force for the foam phantom was comparable to the specimen measurements and the parametric model provided comprehensible characteristic parameters. Based on the resulting force during needle insertion into human vertebrae, a possible foam recipe for manufacturing artificial segments was found. Furthermore, the parametric model provides characteristic parameters for the assessment of phantoms as well as the development of its production process.},

Doi = {10.1109/EMBC.2012.6347306},

Url = {http://dx.doi.org/10.1109/EMBC.2012.6347306}

}[Bibtex]

@Article{Hollensteiner2013a,

Title = {Artificial Vertebrae for a Novel Simulator in Minimally Invasive Spine Surgery.},

Author = {Hollensteiner, Marianne and Fuerst, David and Schrempf, Andreas},

Journal = {{Biomed Tech (Berl)}},

Year = {2013},

Abstract = {Currently the surgical training of vertebral augmentation techniques is performed on patients or specimens. To improve patient safety, the development of a novel patient simulator was initiated. Artificial vertebrae should be integrated to provide realistic haptic feedback. In a previous study, resulting forces during transpedicular needle insertions into formalin-fixed vertebral specimens were measured. Based on these results, a specific polyurethane foam recipe was covered by different resin shells. The resulting insertion forces for the artificial vertebrae were comparable to the specimen measurements. Based on the resulting force during needle insertion into human vertebrae, a suitable material composition for manufacturing artificial vertebral segments was found.},

Doi = {10.1515/bmt-2013-4409},

Url = {http://dx.doi.org/10.1515/bmt-2013-4409}

}[Bibtex]

@Article{Hollensteiner2014a,

Title = {Artificial muscles for a novel simulator in minimally invasive spine surgery.},

Author = {Hollensteiner, Marianne and Fuerst, David and Schrempf, Andreas},

Journal = {{Conf Proc IEEE Eng Med Biol Soc}},

Year = {2014},

Pages = {506-509},

Url = {https://doi.org/10.1109/EMBC.2014.6943639},

Abstract = {Vertebroplasty and kyphoplasty are commonly used minimally invasive methods to treat vertebral compression fractures. Novice surgeons gather surgical skills in different ways, mainly by ?learning by doing? or training on models, specimens or simulators. Currently, a new training modality, an augmented reality simulator for minimally invasive spine surgeries, is going to be developed. An important step in investigating this simulator is the accurate establishment of artificial tissues. Especially vertebrae and muscles, reproducing a comparable haptical feedback during tool insertion, are necessary. Two artificial tissues were developed to imitate natural muscle tissue. The axial insertion force was used as validation parameter. It appropriates the mechanical properties of artificial and natural muscles. Validation was performed on insertion measurement data from fifteen artificial muscle tissues compared to human muscles measurement data. Based on the resulting forces during needle insertion into human muscles, a suitable material composition for manufacturing artificial muscles was found.}

}